As shipbuilding technology continues to advance towards larger scales, greater intelligence, and higher precision, the accuracy requirements for original ship components are also increasing annually. In response to the demands of shipbuilding, CHTEM is continuously innovating and upgrading our research and development of boring and milling machines.

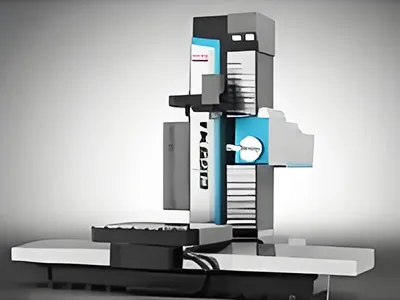

With two decades of dedicated experience in the research, development, and manufacturing of boring and milling machines, CHTEM can provide customized machine tool solutions tailored to the specific machining characteristics and dimensions of shipbuilding production.

Our boring and milling machines are equipped with advanced CNC systems and automatic tool exchange devices, enabling single-clamping multi-process machining of complex parts, which significantly improves processing efficiency and precision stability.

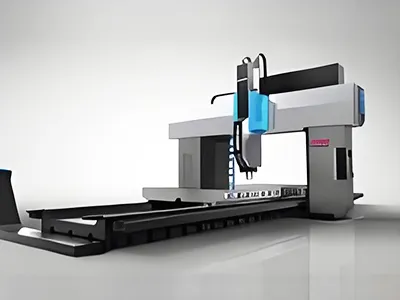

The integration of intelligent processing monitoring and compensation systems allows for real-time detection of dimensional deviations during the machining process and automatic adjustment of machining parameters, ensuring that every machined component meets stringent quality standards.

The application of multi-axis linkage technology enables our boring and milling machines to machine more complex spatial curved surfaces and special-shaped structures, meeting the processing needs for uniquely shaped components in shipbuilding and bringing more possibilities and innovation to ship design and manufacturing.