The engine block stands as one of the most critical components of an engine. Due to its significant size and stringent precision demands, high-accuracy boring and milling machines are essential for its production and processing.

Engine block machining, cylinder head machining, crankshaft machining.

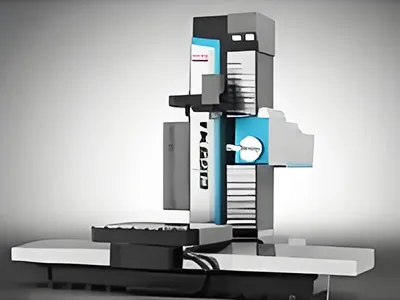

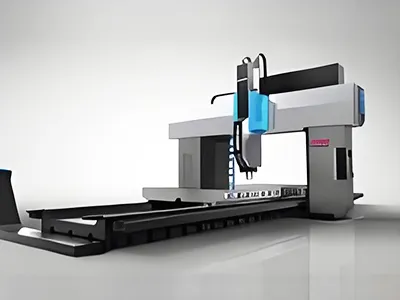

With two decades of dedicated experience in the research, development, and manufacturing of boring and milling machines, CHTEM can provide customized machine tool solutions tailored to the specific machining characteristics and dimensions of engine manufacturing.

Our company's boring and milling machines can precisely bore cylinder holes, strictly controlling bore diameter tolerances, cylindricity, and surface roughness. For example, during the machining of automotive engine blocks, our boring and milling machines can control the cylinder bore diameter tolerance within ±0.01 mm, the cylindricity error to less than 0.005 mm, and achieve a surface roughness of Ra0.4 - Ra0.8 micrometers. Such high precision ensures excellent sealing and lubrication between the piston and cylinder wall, reducing gas leakage and wear, and improving engine power output and fuel economy.

For a series of complex hole systems on the engine block, such as crankshaft bearing holes and camshaft bearing holes, our boring and milling machines, through precise positioning and multi-axis linkage machining, guarantee positional accuracy requirements such as coaxiality and parallelism between the holes. This ensures the smooth operation of critical components like the crankshaft and camshaft, reduces vibration and noise, and extends the service life of the engine.