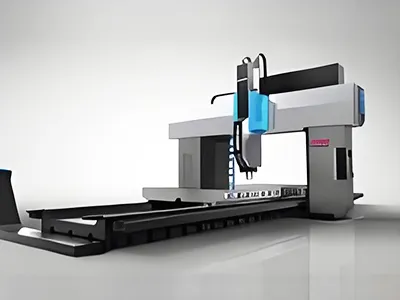

CNC boring and milling machines are frequently employed in the manufacturing of essential large-scale components for mining machinery, including gears, shafts, and housings, such as the eccentric shafts of crushers and the cylinder flanges of ball mills. These components demand high levels of precision and quality, which CHTEM's boring and milling machines are designed to guarantee in terms of dimensional accuracy and surface finish.

Examples include gearbox housings, crusher frames, transmission shafts in mining equipment, crusher main shafts, flywheels in mining machinery, brake discs, conveyor supports, and crusher support brackets.

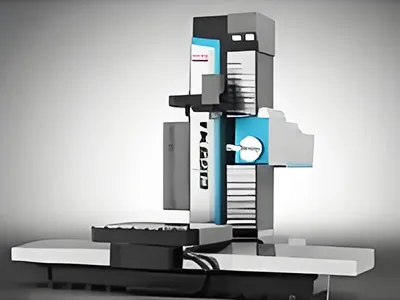

With two decades of dedicated experience in the research, development, and manufacturing of boring and milling machines, CHTEM can provide customized machine tool solutions tailored to the specific machining characteristics of various mining machinery components.

Our CNC boring and milling machines are capable of performing a wide array of machining operations, including boring, drilling, milling, and slotting. This enables complex process combinations to be completed on a single machine, reducing production workflows and equipment investment. For example, in the manufacturing of slewing platforms for mining excavators, our machines can complete plane milling and hole system machining in a single setup.