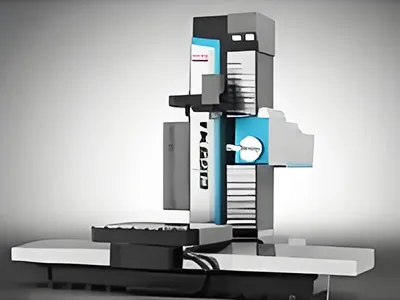

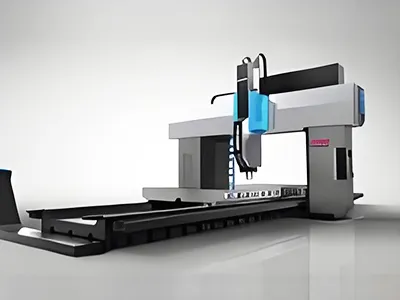

Energy equipment is often characterized by its large scale, complex structure, and extremely high precision requirements. For instance, the hub, a vital component connecting the blades and the main shaft in wind power generation equipment, necessitates precise machining of mounting holes by boring and milling machines to ensure tight fitting and uniform stress distribution across all connecting points. Consequently, there are specific demands on the machining equipment's size range and accuracy. The machining precision of the finished product directly impacts the stability and reliability of the wind turbine during high-speed operation. CHTEM possesses extensive manufacturing experience in boring and milling machines required for energy equipment production, enabling us to provide you with high-quality boring and milling machine equipment.

Processing ports and inner surfaces of wind turbine towers, machining wind turbine hubs, machining bearing mounting holes, machining blade connection areas, machining wind turbine main shafts, machining connecting flanges, machining wind turbine gearboxes, and end caps.

With 20 years of expertise in the research, development, and manufacturing of boring and milling machines, CHTEM can provide customized machine tool solutions tailored to the specific machining characteristics and dimensions of various energy equipment. For example, in the manufacturing of wind turbines, our boring and milling machines can be used to process critical components such as hubs and bases.

Our boring and milling machines offer superior machining accuracy. By effectively controlling the precision of finished parts, we can significantly reduce vibration and noise, thereby improving power generation efficiency and lowering equipment failure rates.