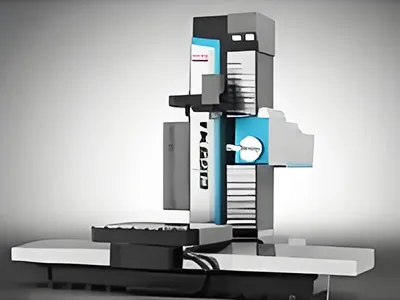

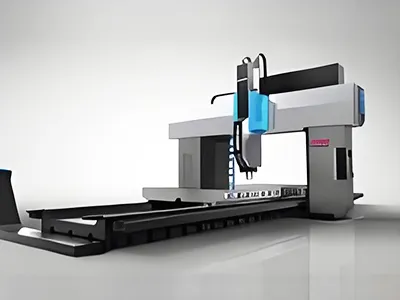

CHTEM operates a 90,000 m2 state-of-the-art manufacturing facility, equipped with comprehensive capabilities in the design, development, production, testing, and manufacturing of a full range of CNC and digital readout boring and milling machines. We are proud to be among the first in our industry to achieve ISO9001 international quality management system certification. Our production process is meticulously organized into multiple stages, including casting, machining, assembly, and debugging, supported by 60 sets of diverse processing and testing equipment.

The machine bed, worktable, column, and power head housings of our machine tools are all manufactured using high-strength cast iron (HT250) and a resin sand casting process, followed by two thermal aging treatments. This ensures excellent vibration damping, thermal stability, and high overall structural strength and rigidity.

The ram and ram seat are critical components. To guarantee superior wear resistance and high tensile strength, the ram is made from high-quality QT600-3 ductile iron, while the ram seat utilizes high-quality QT500-7 ductile iron. The outer four surfaces undergo precision machining to serve as smooth and accurate slideways for ram movement.

For steel plates, angle steel, and section steel (profiles), we maintain long-term partnerships with qualified suppliers, sourcing directly to ensure material quality and consistency.

Upon arrival of the cast components, our skilled machining personnel follow strict production plans and process requirements to machine the parts. This includes operations such as boring holes, milling planes, milling grooves, and contour milling on parts of various shapes and sizes. We carefully select cutting tools, fixtures, and cutting parameters based on the precision requirements of each part. For instance, high-precision three-jaw chucks or hydraulic chucks are used to clamp circular parts, effectively minimizing clamping deformation and enhancing machining accuracy. For thin-walled parts, specialized clamping methods like vacuum suction fixtures are employed to prevent deformation caused by clamping forces. Currently, our machining department achieves a 99% qualification rate for all component products.

After the precision machining of parts is completed and they meet quality standards, they are transferred to the semi-finished product warehouse, where warehouse managers record their receipt. The sub-assembly and assembly workshops then retrieve these parts according to the production schedule to assemble power heads, gearboxes, and milling heads, ensuring rigorous quality control. Once the sub-assembled components pass inspection by quality engineers, they are moved to the final assembly workshop.

For equipment oil tanks and external protective covers, processes such as blanking and welding are required. Our welding workshop personnel perform these tasks according to production plans and welding process specifications. Upon completion, the welded components undergo quality inspection. Qualified products are then transferred to the grinding and painting workshop for painting according to production plans, technical specifications, and painting operation procedures. Painted components are then moved to the final assembly workshop.

The final assembly workshop retrieves components from the warehouse and assembles the columns and rotary tables according to production plans and process operation procedures. Subsequently, the semi-finished power heads, gearboxes, milling heads, and other components from the sub-assembly workshop are installed onto the main structure of the machine tool.

The electrical components and control systems used in our equipment are sourced from internationally leading manufacturers. For example,

Our long-standing partnerships with these manufacturers ensure not only direct procurement but also comprehensive service and after-sales support.

We implement comprehensive quality inspection throughout the entire production and processing process. For raw materials, we verify dimensions, hardness, and other basic properties to ensure they meet requirements. During the semi-finished product stage, the focus is on inspecting critical dimensions and machining accuracy. Final product inspection involves a thorough examination of all dimensions, shapes, and surface quality. We utilize various inspection methods, including manual measurement tools, coordinate measuring machines (CMM), and optical vision measurement systems. Simple dimensional checks are performed with calipers and micrometers, while complex shape and positional accuracy inspections, such as the positional accuracy of hole systems on box-type parts, are conducted using high-precision CMMs.

We have also established a quality feedback mechanism. When any precision deviation is detected, the information is promptly relayed to the machining and process personnel. For instance, if a dimension is found to be out of tolerance during final inspection, the quality department immediately notifies the production team and process department. Process engineers analyze the feedback, determine whether the issue is related to equipment, operator error, or process parameters, and then implement appropriate corrective actions, tracking their effectiveness to ensure machining accuracy is effectively controlled.

Once the assembled equipment passes self-inspection, mutual inspection, and specialized inspection, customers are notified for pre-delivery acceptance. Upon successful customer acceptance, we arrange logistics for shipment.

After shipment, our installation team travels to the customer's site for equipment installation. Following installation, the equipment undergoes commissioning and final acceptance. Upon successful final acceptance, the warranty period begins. During the warranty period, our company resolves any issues free of charge. Beyond the warranty period, our after-sales service personnel respond promptly to equipment problems, and if on-site service or replacement parts are required, we charge a reasonable cost.