CNC boring and milling machines are frequently employed in the manufacturing of essential large-scale components for mining machinery, including gears, shafts, and housings, such as the eccentric shafts of crushers and the cylinder flanges of ball mills. These components demand high levels of precision and quality, which CHTEM's boring and milling machines are designed to guarantee in terms of dimensional accuracy and surface finish.

Energy equipment is often characterized by its large scale, complex structure, and extremely high precision requirements. For instance, the hub, a vital component connecting the blades and the main shaft in wind power generation equipment, necessitates precise machining of mounting holes by boring and milling machines to ensure tight fitting and uniform stress distribution across all connecting points.

As shipbuilding technology continues to advance towards larger scales, greater intelligence, and higher precision, the accuracy requirements for original ship components are also increasing annually. In response to the demands of shipbuilding, CHTEM is continuously innovating and upgrading our research and development of boring and milling machines.

The engine block stands as one of the most critical components of an engine. Due to its significant size and stringent precision demands, high-accuracy boring and milling machines are essential for its production and processing.

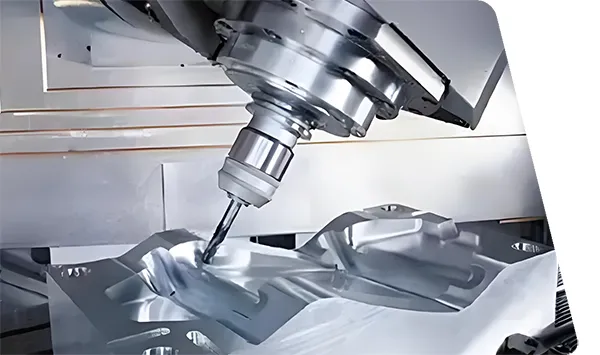

The aerospace industry demands extremely high machining precision. Even minute errors can lead to severe consequences. Therefore, for all aerospace equipment manufacturing companies, selecting the appropriate high-precision boring and milling machine equipment is a critical factor determining the quality of their products.

Construction machinery factories, due to the complex nature of their applications, often have specific demands for the mechanical properties and dimensional accuracy of materials. The ability to machine high-precision construction machinery components from high-strength raw materials is a key consideration for many machinery manufacturing enterprises, where high-quality boring and milling equipment plays a vital role.

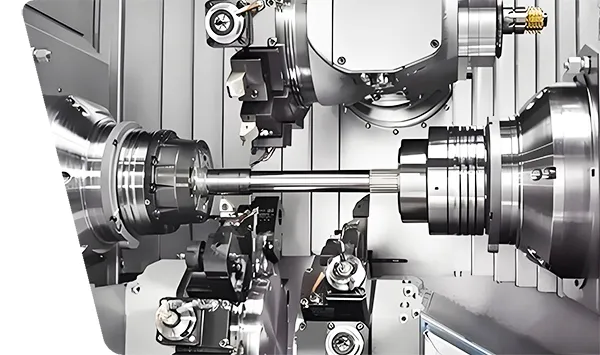

Boring and milling machines have numerous important applications in both upstream and downstream processes related to forging technology. All critical components of forging equipment, due to their material properties and dimensions, rely on the precise machining capabilities of boring and milling machines for their manufacturing.